Once exploration confirms a viable deposit, the focus shifts from discovery to design. Every decision now depends on understanding the land, its terrain, structure, water flow, and surrounding environment. Mistakes at this stage can lead to costly redesigns, unstable slopes, or inefficient haul routes that drain both fuel and time.

That’s where Geographic Information Systems (GIS) step in. By linking topographic, geological, and environmental data within a single spatial model, GIS gives mining teams a real-world view before ground is broken. Instead of relying on fragmented drawings or spreadsheets, planners can visualise the mine layout, test options, and refine plans based on real conditions. The result is a design that’s safer, more efficient, and easier to communicate across teams and regulators.

Modern mining depends on data-driven decisions, and GIS is now at the heart of how those decisions are made.

GIS–CAD Integration: From Models to Measurable Planning

For years, engineers relied on CAD tools like AutoCAD Civil 3D, Surpac, and MicroStation to draft mine layouts. These tools excel in precision but often operate in isolation. GIS bridges that gap by bringing real-world context into the design environment.

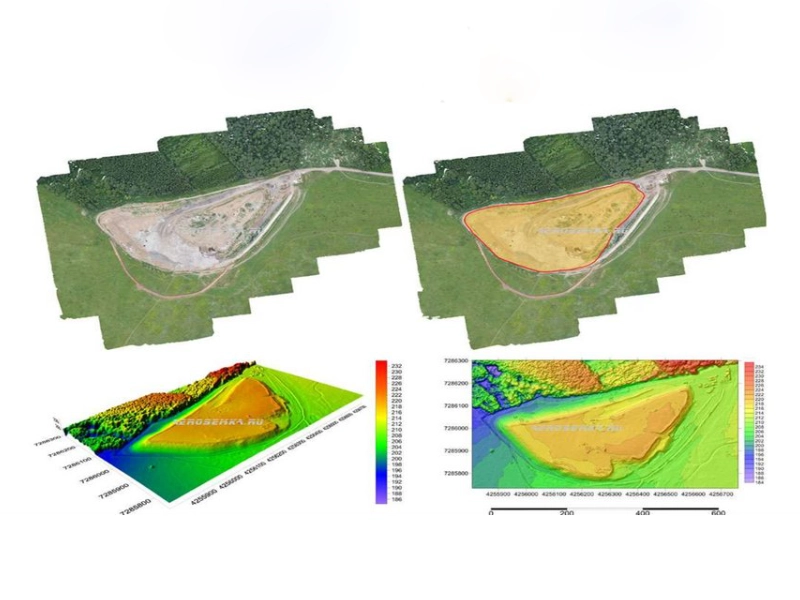

Digital Elevation Models (DEMs), topographic layers, and subsurface geological maps can all be imported into GIS, where they align perfectly with CAD geometry. This integration allows engineers to assess slope angles, terrain constraints, and access routes directly over satellite imagery or terrain grids. Updates made in GIS can then feed back into CAD models, ensuring both platforms stay synchronised.

With tools like ArcGIS Pro and QGIS, engineers can overlay hundreds of data layers, land ownership, infrastructure, hydrology, and environmental sensitivity, without losing accuracy. Cloud-based collaboration now means planners, surveyors, and environmental officers can view and adjust designs in real time. This connected workflow reduces manual transfers and eliminates errors caused by mismatched coordinate systems.

In short, GIS turns traditional drawings into interactive spatial models, making every design choice measurable and defensible.

Applications of GIS in Mine Planning and Design

1. Pit and Slope Design

In open-pit mining, a few degrees in slope angle can decide whether a wall remains stable or fails under stress. GIS gives engineers a spatially accurate view of pit geometry against real terrain. By analysing DEMs and geotechnical data together, planners can model slope behaviour, identify weak zones, and test different cut angles long before excavation begins.

When integrated with mine-planning suites such as Surpac or Vulcan, GIS adds precision to pit optimisation. Designers can visualise how the pit evolves with each phase, forecast material volumes, and understand how changes in design affect overall safety margins. The outcome is a pit design that balances extraction efficiency with long-term stability.

2. Haul Road Optimisation and Logistics Planning

Haulage can account for up to 60% of an open-pit mine’s operational costs. Poorly designed haul roads lead to unnecessary fuel burn, slower cycle times, and higher maintenance costs. GIS helps prevent that by modelling road routes across real terrain.

Using cost-surface and least-path algorithms, GIS identifies the most efficient routes based on gradient, curvature, and fuel consumption. Engineers can test multiple scenarios, shorter routes versus gentler slopes, and find the best balance between time and energy use. Studies from 2024 show that mines adopting GIS-based haul road design achieved up to 15% fuel savings and improved equipment life through reduced wear.

By linking the haul network to live terrain and production data, GIS also allows for continuous improvement. If rainfall, erosion, or waste dumps alter the landscape, road designs can be adjusted instantly rather than redrawn from scratch.

Read More: GIS in Mining

3. Hydrological Analysis and Drainage Mapping

Water management remains one of the biggest risks in mine design. Runoff that’s not properly controlled can cause slope failures, erosion, and environmental non-compliance. GIS-driven hydrological models allow planners to predict how rainfall will behave across complex terrain.

By combining DEMs with rainfall data and soil permeability, GIS can simulate surface water flow and pinpoint areas prone to flooding or ponding. This lets engineers design drainage systems, culverts, and retention ponds that fit the site’s natural hydrology. Integration with hydraulic modelling tools further helps verify whether proposed systems can handle extreme storm events.

Beyond risk reduction, this proactive mapping supports ESG commitments, ensuring water is managed responsibly from construction through operation and closure.

Want to make haul roads, drainage, and pit designs more efficient?

Get tailored GIS support to model terrain, optimise haulage, and reduce costly rework before construction begins.

📞 Schedule a Call | 📩 Email Us | 💼 Get a Quote Now

Case Example: Phosphate Mine Planning in Saudi Arabia

A phosphate operation in Saudi Arabia provides a clear example of how GIS improves mine layout and design efficiency. The project team used high-resolution DEMs, satellite imagery, and hydrological data to model terrain and water flow before excavation began. By overlaying haul routes, stockpiles, and processing facilities on this digital terrain, planners were able to optimise road alignments and reduce steep gradients.

The result: fuel consumption dropped by nearly 15%, and the number of redesigns during the construction phase was cut in half. GIS also helped visualise dust control zones and buffer areas required by environmental authorities, making regulatory approval smoother and faster. What once took months of manual rework was achieved through a single, integrated platform that linked survey data, CAD drawings, and environmental plans.

Read More: Benefits of Geospatial Data in Analytics

Efficiency Metrics: Measuring the Value of GIS Integration

Mining companies often ask how to quantify the impact of GIS integration. Here’s what leading operators are now tracking:

- Reduced redesign cycles: Projects using GIS–CAD integration report up to 25% fewer late-stage changes, saving both time and consultant fees.

- Haulage efficiency: Fuel use per tonne-kilometre drops by 10–20% when roads are optimised with slope and distance analysis.

- Operational safety: Better slope modelling reduces the likelihood of wall instability and unscheduled downtime.

- Water control: Flood-related work stoppages decline as drainage layouts are tested virtually before construction.

- Regulatory compliance: GIS-based documentation creates auditable evidence for environmental and safety reports, speeding up approvals.

Each of these metrics proves that GIS is not just a design enhancement, it’s a measurable business advantage.

Ready to integrate GIS into your mine design process?

Start your project with GIS Navigator to plan, visualise, and manage every stage, from concept to compliance.

📞 Schedule a Call | 📩 Email Us | 💼 Get a Quote Now

Conclusion

Mine design today demands precision, collaboration, and accountability. GIS connects data from every discipline, geology, engineering, hydrology, and environment, into one spatial framework. Whether it’s designing a pit, modelling drainage, or aligning haul routes, every decision becomes grounded in real-world context.

At GIS Navigator, we help mining engineers and project planners integrate GIS into their existing workflows. From DEM analysis to full CAD synchronisation, our experts ensure that your designs are efficient, safe, and compliant, before the first shovel hits the ground.

Discuss your mine design data integration with GIS Navigator experts.

We’ll review your existing setup, identify areas for improvement, and show you how GIS can turn your designs into measurable performance gains.